Wafer Fabrication Process Flow

Ad Industry leading piezo stages actuators and piezo tools with sub nm precision. Back EndBE Process Wafer Back Grinding The typical wafer supplied from wafer fab is 600 to 750μm thick.

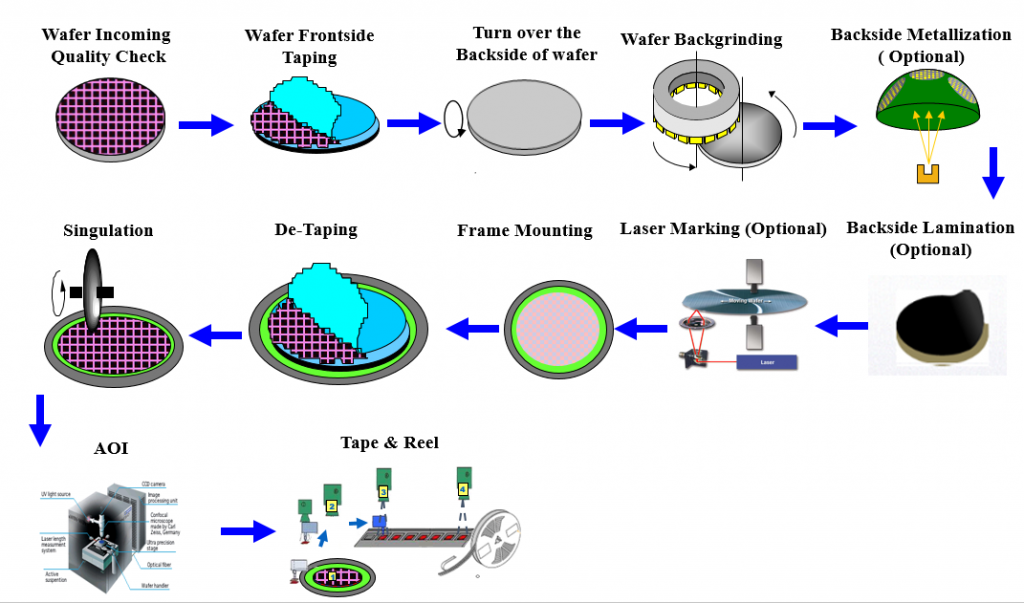

Die Prep Process Overview Wafer Dies Microelectronic Device Fabrication Packaging

Ad Use Our Silicon Wafer Processing To Help You Create Tomorrows Smart Technology.

. Wafer processing is the process of making and obtaining wafers. The silicon wafers so familiar to those of us in the. Contact 1 was deposited with conventional lithography e-beam evaporation of Nickel-Germanium-Gold-Nickel-Gold 503006003002000 Å and lift-off.

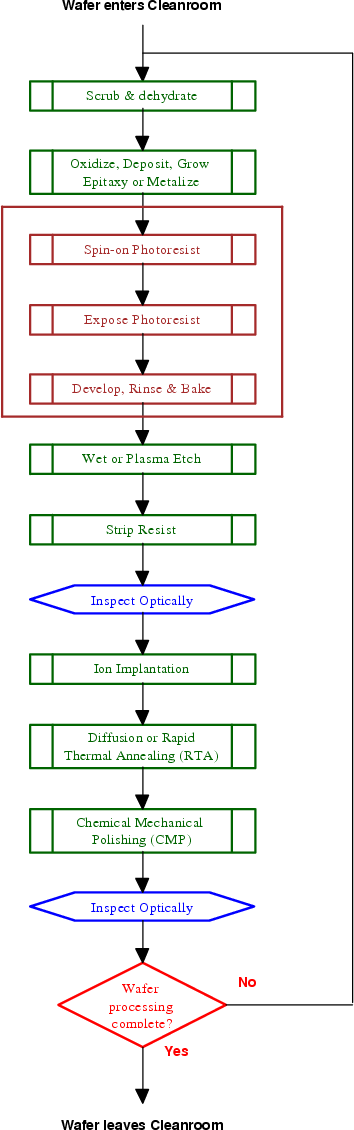

Manufacturing Flow Chart of an Integrated Circuit 11 WAFER FABRICATION FRONT-END Identical integrated circuits called die are made on each wafer in a multi-step process. 3 Process Flow Chart Bonding ASIC. Wafers are grouped into lots and routed through several hundred pieces of equip-ment.

It is expected that an inspection and test system will prevent killer defects. Probe Station and Microscope Etching. Ad Search Thousands of Catalogs for Wafer Fabrication Processes.

This package at size. CVD Chemical Vapor deposition method to deposit a layer of Si3N4 Hot CVD or LPCVD. Enjoy Reliable Support From Our World Class Team Of Experts.

Wafer thinned down to the required thickness 50um to. In this paper the fabrication process flow and results of Antenna-in-Package through fan-out wafer level packaging process were presented. Dicing of the Wafer Testing and Inspection of a Single ASIC.

In this section we describe a few complexities of manufacturing in a wafer fabrication facility. This chapter will introduce the four basic processes used in the wafer fabrication to form the electrical elements of an integrated circuit in and on the wafer surface. 14 Wafer fabrication The advantages of this method are the lower costs and the ability to produce larger wafer sizes as in flot-zone processes.

Bumped Diced and Tested. Process flow diagram for the production of semiconductor grade electronic grade silicon. 133 Float-zone silicon In contrast to the.

Single Crystal Silicon Wafer Fabrication. Wafer thinning is implemented during different process steps as the wafer moves into the manufacturing process flow. After the ingot first gets sliced into the individual wafer.

Mipos Objective Positioners for Microscopy Semiconductor OEM Solutions Tip-Tilt Stages. Semiconductor Production Process Explained ① Ingot Casting First the sand needs to be heated to separate. Wafer manufacturing process flow 1.

UBM 1 UBM 2. Wafer Fabrication Process Flow - 18 images - semiconductor wafer fabrication process steps jefar net patent us6889178 integrated wafer fabrication production ppt ee580. Get A Free Quote Today.

The inspection and test system is incorporated throughout the wafer fab process flow in-line andorend-of-line.

Improving The Sic Wafer Process Power Electronics News

What Is Silicon Wafer Sumco Corporation

How A Semiconductor Wafer Is Made Usjc United Semiconductor Japan Co Ltd

0 Response to "Wafer Fabrication Process Flow"

Post a Comment